Aluminum Windows, Doors & Curtain Wall Solutions

We provide one-stop solutions for aluminum doors, windows and curtain walls for projects worldwide, from scheme design, performance and compliance verification, prototyping and testing, mass production and delivery to after-sales service.

APRO's Services

Pre-Sales Service

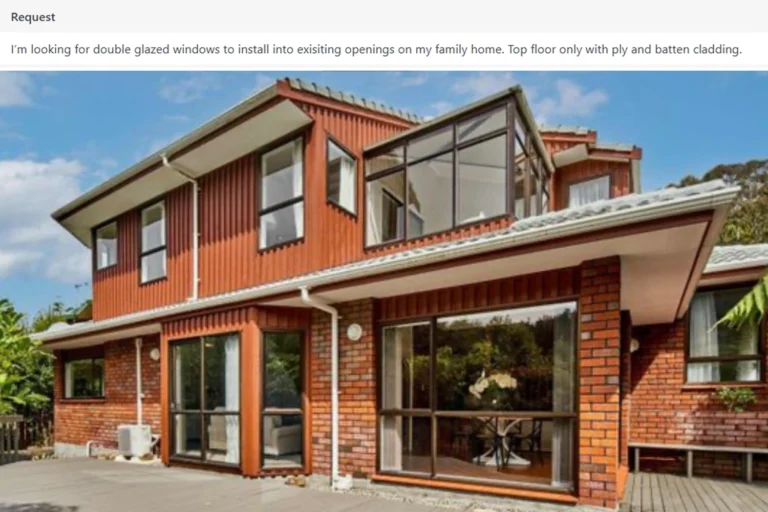

Depending on the project type, we typically begin with online discussions with clients to clarify their functional and performance goals (U-value, STC/Rw, wind pressure resistance, etc.), regulatory and acceptance requirements, budget and timeline, and aesthetic preferences. We also collect facade/floor plans, node specifications, and on-site data.

Following this, we schedule an on-site measurement appointment. Using laser rangefinders and levels, we verify opening dimensions, verticality, and foundation conditions, confirming load-bearing capacity, finishing details, and waterproofing pathways. We then conduct a review meeting with the civil engineering/curtain wall/interior design teams to ensure key points are understood.

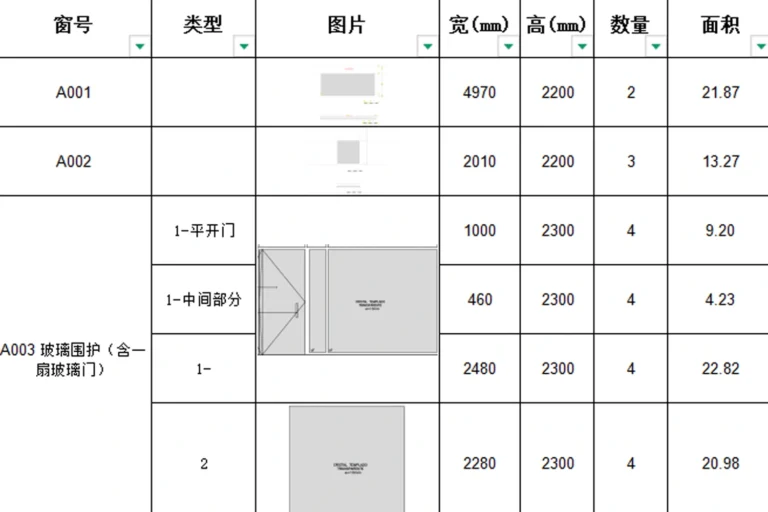

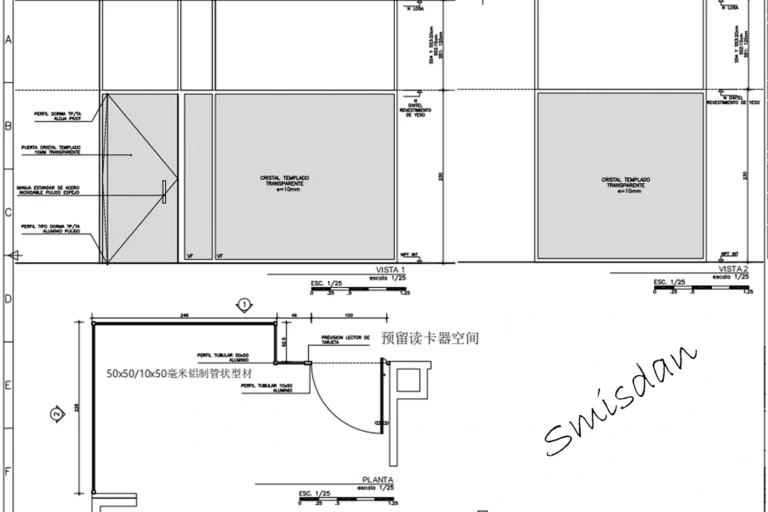

Project drawing design

Starting with initial communication and on-site condition verification, we produce a complete set of plan, elevation, and section drawings, along with detailed specifications of key nodes, focusing on opening dimensions, opening functions, and drainage/airtightness strategies. Simultaneously, we develop a hardware list, mounting base specifications, and finishing details.

To minimize rework risks, we comprehensively plan out dimensions, profile types/cavities, material selection, and opening methods and functions (such as limit switches, linkages, and electric operation) during the design phase. Delivery formats supported include DWG/DXF/PDF.

Compliance and Certification (by project country/region)

After the case is initiated, we will first establish a list of applicable standards and a testing plan to ensure alignment with local regulations from the outset. Commonly used standards include ASTM E283/E331/E330, AAMA 101/2604/2605, NFRC, EN 14351-1, EN 13830, CE, etc.

Regarding indicators such as airtightness, watertightness, wind pressure resistance, sound insulation (STC/Rw), surface treatment weather resistance, and profile chemical/mechanical properties, we will provide a design and verification path and create a traceable data archive.

Transportation and Trade

Based on your project timeline and budget, we will match you with the optimal combination of sea/air/rail freight, and design customized packaging solutions including wooden crates/steel frames, corner fittings, desiccants, and barcode traceability to minimize damage during transit.

Regarding documentation, we prepare a complete set of documents, including commodity inspection certificates, certificates of origin, packing lists, invoices, and bills of lading, and provide customs clearance assistance.

For delivery terms, you can choose EXW/FOB/CIF/DDP (including insurance); if you choose DDP, we will coordinate customs clearance and last-mile delivery to deliver the goods to your designated location.

Product customization (all parameters can be configured)

We will determine the dimensions, materials (6063-T5/T6, etc.), colors (RAL/AAMA), and finishes (powder/anodized/wood grain/fluorocarbon) item by item, based on your performance goals (such as U-value, STC/Rw, wind resistance) and style preferences.

The glass system can be flexibly combined from tempered/laminated/insulated/Low-E/argon-filled/warm-edge options; hardware brands, appearances, and functions (such as multi-point locks, damping, door closers) can be specified.

For integrated solutions, we can also integrate screens, built-in blinds, sunshade systems, access control/motors, smoke extraction/wind sensors, and other accessories; shapes and opening methods cover curved, triangular, irregular shapes, and casement/tilt/sliding/lift-and-pull/folding/concealed sashes, etc.

On-site support for large-scale projects

For large-scale or technically complex projects, we can send engineers to the site to provide technical briefings, guide sample construction, and supervise key processes. During construction, we address issues, inspect quality, coordinate progress, and cooperate with third-party testing and acceptance during the completion phase, compiling as-built documentation to help projects be delivered on schedule and to standards.

APRO Offers Solutions For Different Scenarios And Regions.

By Application

Choose an application to get a ready-to-spec package. For each scenario we recommend the right system (casement, tilt-turn, sliding, storefront, unitized), glass build-ups and hardware, and align with local codes on energy, acoustic, air/water/structural and security. Upload your drawings to receive submittals, DWG/PDF/Revit details, and a budget quote.

By Application

Choose an application to get a ready-to-spec package. For each scenario we recommend the right system (casement, tilt-turn, sliding, storefront, unitized), glass build-ups and hardware, and align with local codes on energy, acoustic, air/water/structural and security. Upload your drawings to receive submittals, DWG/PDF/Revit details, and a budget quote.

Compliance and Certification

APRO Service Process

Our Proud Projects

Aluminum Doors, Windows & Curtain Wall Solutions - FAQ

Do you support fully customized sizes and opening methods?

Yes. Please provide your facade/floor plan, opening dimensions, target U-value/acoustic/wind pressure, etc., and our engineers will provide suggestions within 24–48 hours.

What is the delivery cycle?

Typically 2–3 weeks for samples, 4–8 weeks for mass production; this may be adjusted during peak seasons or for special surface treatments/glass configurations, subject to the actual contract.

Do you provide on-site installation?

We provide detailed specifications, installation guidelines, and remote technical support; if local installation is required, we can assist in connecting with partner installers.

Can you provide third-party testing or certification?

We can provide ASTM/AAMA testing services and reports as needed for the project; CE/NFRC documentation support is available for some regions.

What is the warranty policy?

Warranty periods are set separately for profiles/surfaces/hardware/glass (subject to the contract), and a maintenance manual and spare parts plan are provided.

Does it support BIM/Revit files?

We can provide family files or parametric node examples as needed to facilitate design collaboration.

How to select a model for highly corrosive coastal environments?

We recommend enhancing the coating system (AAMA 2605, etc.), using stainless steel fasteners and corrosion-resistant hardware, and optimizing drainage and maintenance frequency.