Canada Solutions — Doors, Windows & Curtain walls

We work closely with Canadian architects, builders and façade contractors, integrating building code compliance, NAFS/CSA performance requirements, energy efficiency and harsh winter climate conditions into one complete solution.

For each province and city, we recommend suitable aluminium profiles, glass packages and installation details, helping you reduce redesign and communication costs while delivering façades that not only pass review, but also perform reliably for decades in the Canadian climate.

Certifications and Guarantees for Canada Projects

For Canada window, door and curtain wall projects, proven test data and clear documentation are essential for meeting code, passing municipal review and coping with long, cold winters. Owners and consultants want to see not only drawings, but certified performance values for air, water, structural and energy efficiency.

Our aluminium systems can be designed and tested in line with the National Building Code of Canada and provincial requirements, using NAFS / CSA standards for fenestration performance and relevant Canadian energy-rating programs. We support you with Canadian test reports, certificates and warranty documents so your façade package is easier to approve and simpler to maintain over the life of the building.

Canada Codes & Certifications

We provide performance ratings and reports to Canadian standards, including NAFS / CSA for air, water and structural performance, as well as supporting documentation for Canadian energy-efficiency programs and other project-specific requirements. This helps your windows, doors and curtain walls demonstrate clear compliance in the Canadian market.

Service & Warranty Support

For projects across Canada, we stay involved beyond shipment with technical assistance, replacement parts and coordination with your local installers. Our warranties and ongoing support are designed around Canadian conditions, helping your aluminium window, door and curtain wall systems remain weathertight, efficient and reliable year after year.

Challenges and solutions we encountered in our project in Canada

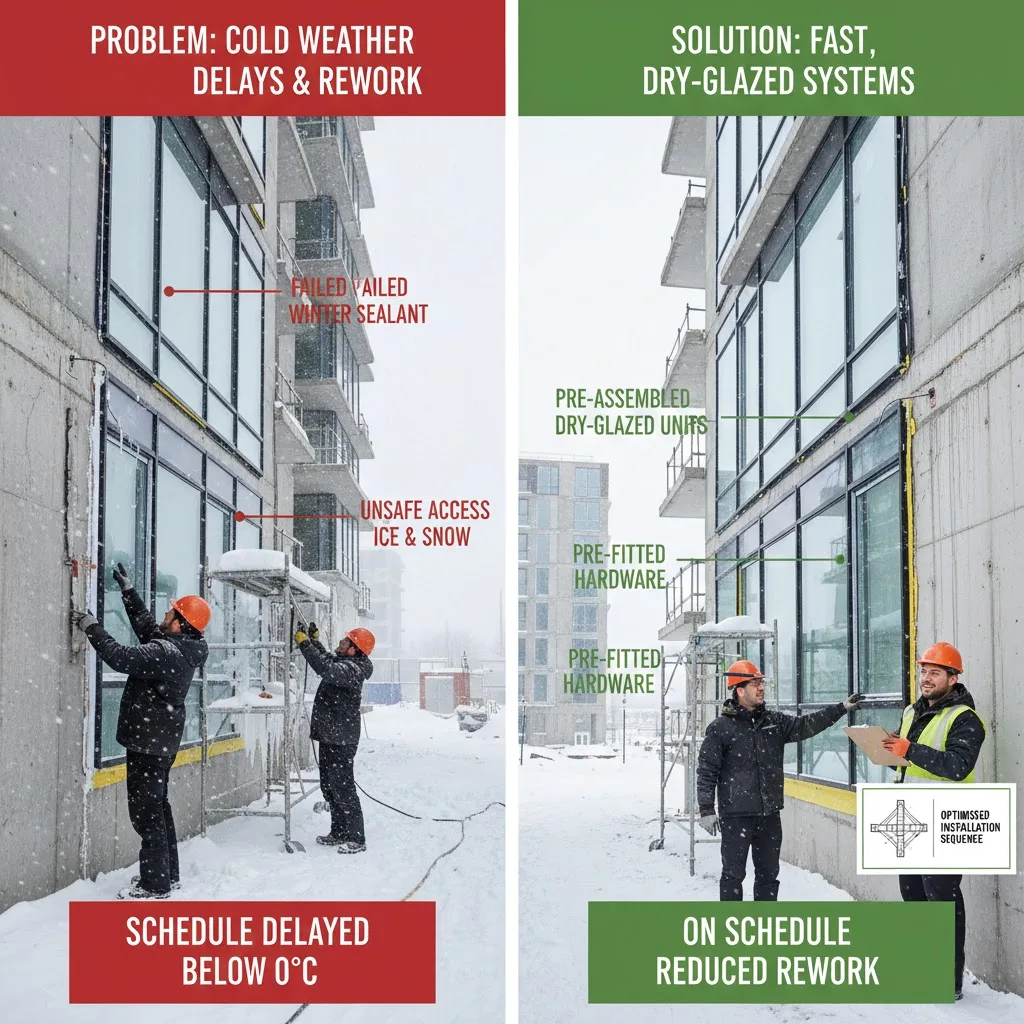

Short installation seasons & freezing job sites

Pain in Canada:

On many Canadian projects, façade installation has to be finished between late spring and early fall. Once temperatures drop below 0°C, sealants cure slowly or fail, snow and ice make access unsafe, and schedule delays become very expensive.

Our solution:

We design pre-assembled window, door and curtain wall units with dry-glazed systems and simple anchoring so installers can close in the building quickly. Hardware is pre-fitted, fixing points are clearly marked, and we provide installation sequences optimised for short Canadian construction seasons, reducing cold-weather rework.

Keeping air & vapour barriers continuous around frames

Pain in Canada:

NBCC and provincial codes put strong emphasis on air-tightness and vapour control. On site, the junction between wall air/vapour barrier and the window or curtain wall frame is often the weakest point, leading to drafts, condensation and failed blower-door tests.

Our solution:

For typical Canadian wall build-ups (wood stud, steel stud, concrete), we provide tested interface details and 3D node drawings showing exactly how to connect the air and vapour barrier to our frames. Pre-formed sill pans, back dams and membrane kits are specified with our systems so installers can achieve continuous AB/VB lines without guesswork.

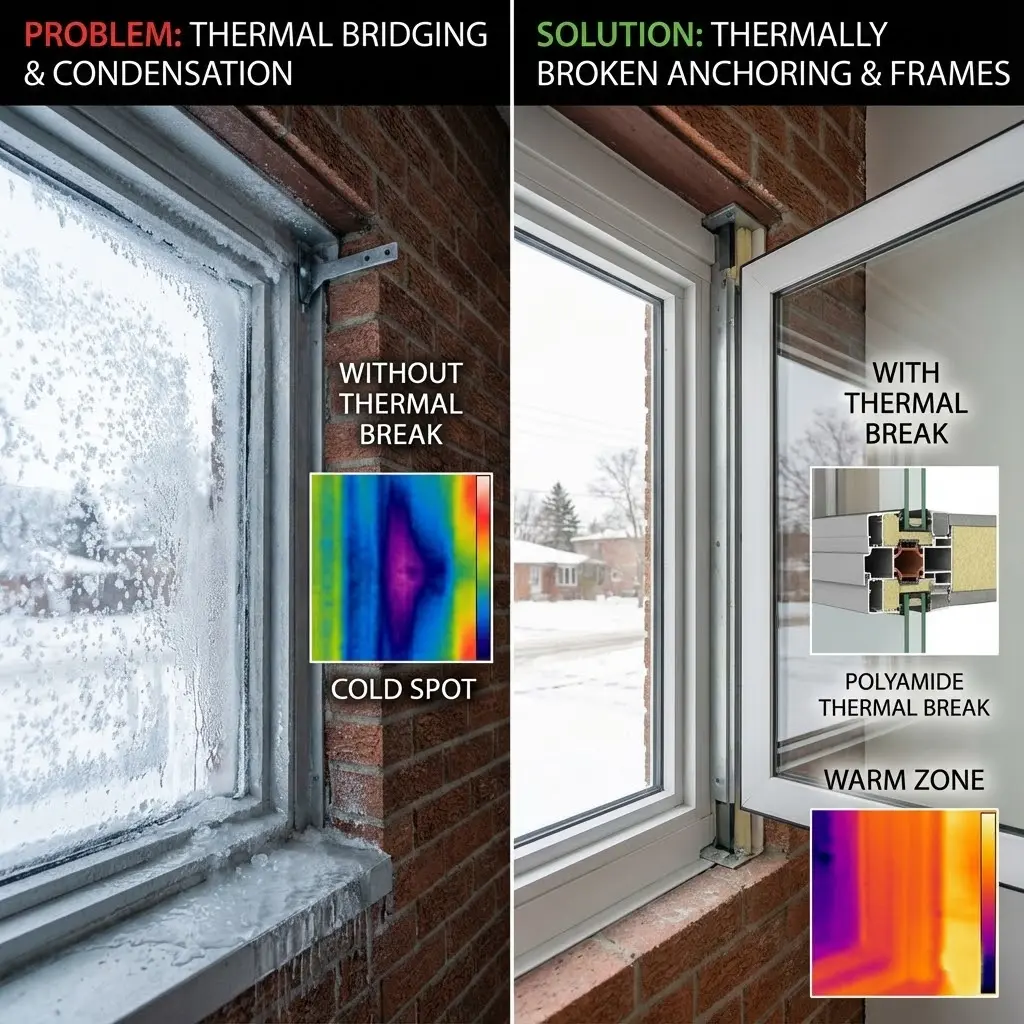

Managing condensation & thermal bridging at anchors and frames

Pain in Canada:

Large temperature differences between inside and outside (-30°C to +30°C) cause cold spots around anchors, perimeter frames and slab edges. Poor detailing here leads to interior condensation, mould, and occupant complaints after handover.

Our solution:

We engineer thermally improved anchoring and frame solutions for Canadian projects: pressure plates and anchors set in warm zones where possible, thermal breaks at key points, and recommended insulation strategies around perimeter frames. Our shop drawings highlight these critical areas so site teams know where to add insulation and sealants to avoid cold bridges.

Out-of-plumb openings in retrofit and replacement projects

Pain in Canada:

Many Canadian buildings from the 1960s–1990s have moved or settled, so window and curtain wall openings are no longer square. Installers spend extra time shimming, cutting back finishes or even sending units back to be remade.

Our solution:

We offer adjustable frame and window wall systems designed for retrofit work in Canada. Frames have tolerance zones, deeper flanges and filler profiles to absorb irregularities, and we provide site-measurement guidelines and checklists so the glazing contractor can order with realistic dimensions and avoid costly remake cycles.

Long-distance logistics & limited on-site storage

Pain in Canada:

Façade materials often travel thousands of kilometres to reach Canadian job sites. Damage in transit, incomplete labelling, and tight urban or remote sites with almost no storage area make installation planning difficult.

Our solution:

We use project-specific packing and labelling for Canadian shipments: units are grouped by elevation and installation order, each crate is clearly marked with drawings references, and knock-down options are available for oversized frames. This reduces handling, minimises damage, and lets contractors stage materials efficiently even on compact or remote Canadian sites.

Coordination between multiple trades on the building envelope

Pain in Canada:

On site, the glazing contractor, framing crew, air-barrier installer, insulation team and interior trades all touch the window and curtain wall openings. Miscommunication leads to penetrations through membranes, missing flashings or conflicting details that are only discovered during inspection or water testing.

Our solution:

We supply coordinated envelope details and trade-by-trade responsibilities for Canadian projects. Our drawings clearly indicate which trade completes each part of the opening (flashing, membrane, insulation, sealant), and we can join pre-start coordination meetings to review critical nodes. This reduces scope gaps and helps the whole team deliver a code-compliant Canadian façade with fewer surprises on site.

APRO’s Project Services for Middle East Canada Projects

Explore Our Product Range

Aluminum Door

Robust aluminium doors offering wide openings, smooth operation and contemporary style.

Aluminum Window

High-performance aluminium windows combining slim sightlines with excellent thermal insulation.

Curtain Wall

Engineered aluminium curtain walls delivering sleek façades and reliable weather protection.

Customizable options

Design Options

Customize frame layouts and opening styles to better match different building types, usage scenarios, and aesthetic preferences.

Size Customization

We tailor every unit to exact site measurements for smoother installation, tighter sealing, and a cleaner façade.

Glazing Types

Select double, triple, or laminated glazing combinations to balance daylight, energy efficiency, acoustic comfort, and safety performance.

Color Choices

Choose standard RAL colors, metallic effects, or woodgrain finishes to coordinate perfectly with surrounding architecture and branding.

Material Selections

Combine high-grade aluminum, certified glass, and durable seals to handle harsh climates, heavy use, and long lifespans.

Hardware Selections

Upgrade handles, hinges, rollers, and locking systems to improve daily operation, anti-theft security, and overall user comfort.

Insulation Options

Optimize thermal breaks, insulated glass, and sealing details to reduce condensation, energy loss, and interior temperature swings.

Contact us

Send your drawings, schedule, and performance targets so our engineering team can design a solution and quotation.

Application Scenarios

Our factory's production process is transparent.

1,Design

2,Material Preparation

3,Machinery Setup

4,Cutting and Machining

5,Frame Construction

6,Glass Fitting

7,Hardware Setup

8,Quality Cntrol

9,Packing

10,Shippment

Aluminum Doors and Windows Solutions in the Canada - FAQ

Which Canadian codes and standards apply to windows, doors and curtain wall?

Windows/doors are qualified to NAFS (AAMA/WDMA/CSA 101/I.S.2/A440) with the CSA A440S1 Canadian Supplement, and energy performance per CSA A440.2. Project compliance also references the National Building Code (NBC) / NECB or the provincial code (OBC, BCBC, etc.). Curtain wall/storefront typically use ASTM E283/E330/E331 for lab tests and AAMA 501 series for façade testing.

Can you provide NAFS/CSA labels and test evidence for Canada?

Yes. We can supply NAFS Performance Class (R/LC/CW/AW) and Performance Grade (PG, Pa) results, plus Canadian-Supplement items (air leakage at 75 Pa, water test pressure, operating force). Labels and submittals are issued when the final configuration matches the rated build-up.

How do you meet Canadian energy targets and ENERGY STAR Canada?

We size thermal breaks, specify Low-E double/triple IGUs with argon and warm-edge spacers, and report U-factor in W/m²·K and SHGC/VT per CSA A440.2. ENERGY STAR eligibility is verified when the rated build-up matches the product label.

How do you control condensation in cold climates?

We review dew point and edge-of-glass risks, increase thermal-break width where needed, use warm-edge spacers, and maintain a continuous interior air seal. We can include CR/ψ-value checks in the design-assist package.

What field testing and commissioning do you support in Canada?

We coordinate ASTM E1105 (field water) and ASTM E783 (field air) for installed windows/doors; façades may use AAMA 503. Acceptance criteria are project-specific and defined in submittals.

How is façade fire and perimeter protection handled?

Where required, exterior wall fire spread is addressed using assemblies evaluated to CAN/ULC-S134; perimeter fire containment/firestopping follows listed systems tested to CAN/ULC-S115 (or project-accepted equivalents). Spandrel/back-pan details are coordinated with the fire consultant.

Do you provide engineering stamps and bilingual documentation?

Yes. P.Eng stamps (most provinces) can be arranged through licensed partners. Submittals, manuals and labels are available in English/French on request for projects in Québec and federal work.