Australia Solutions — Aluminium Windows, Doors & Curtain wall

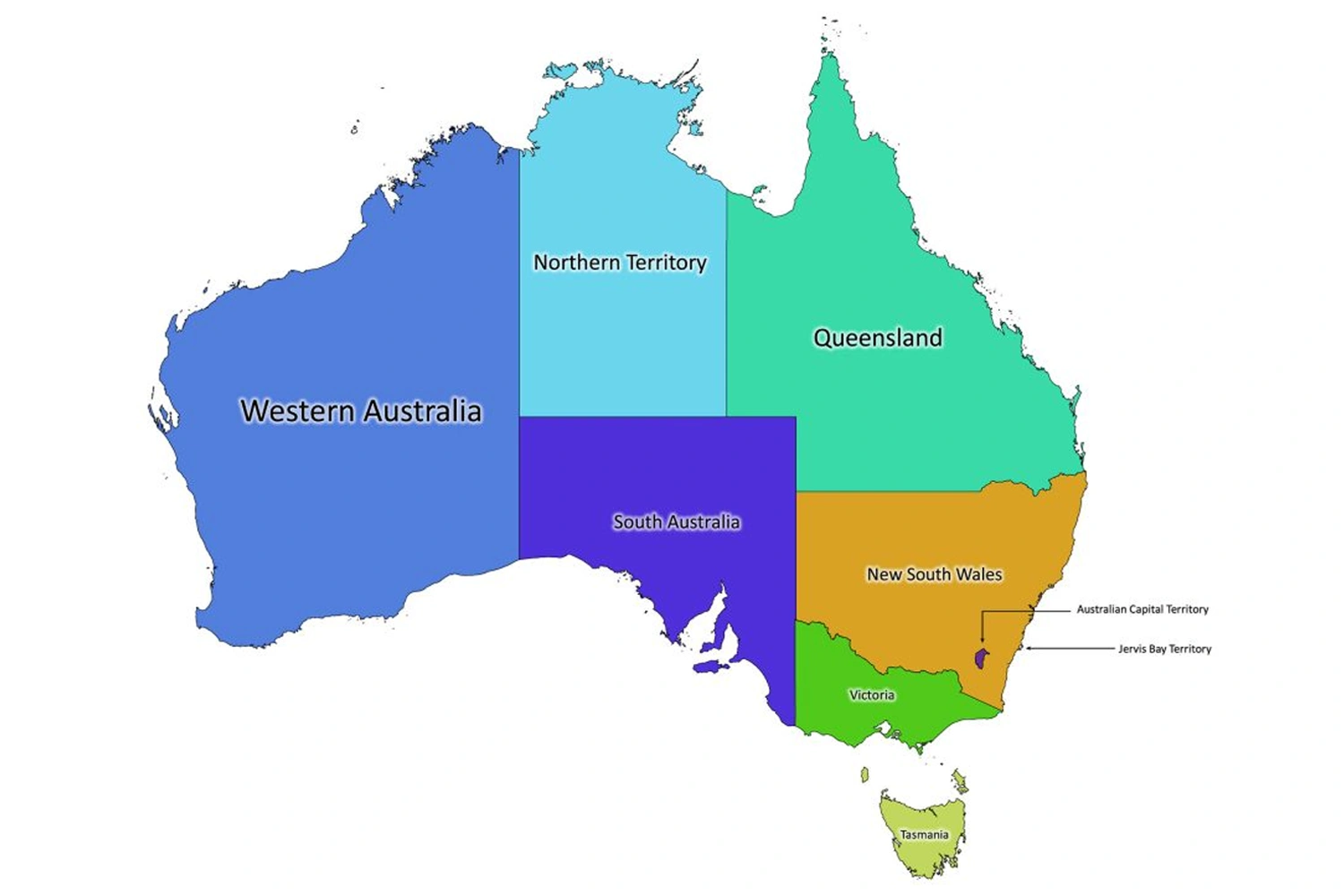

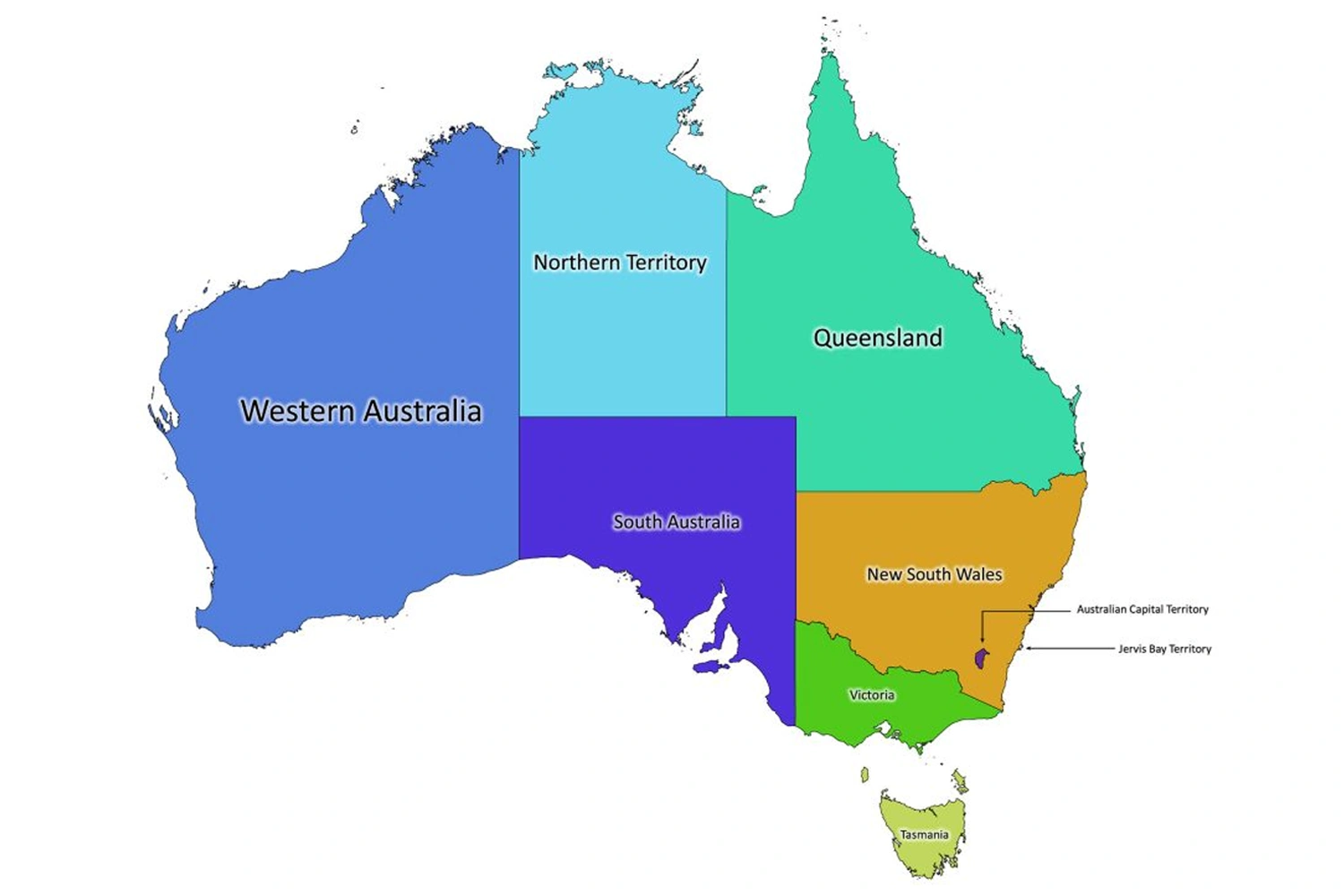

We consistently monitor local project needs, integrating compliance, energy efficiency, wind zones, and wildfire risks into a unified solution framework. We provide specific material and construction recommendations for different states and cities, reducing rework and communication costs, ensuring solutions not only pass review but also withstand long-term use.

Aluminum Door

Structural Capabilities

- Load Capacity: Heavy-duty pulley system, single fan 150–300 kg → Suitable for large glass fans.

- Hardware: Multi-point locks/anti-pry hooks, soft-close door closers → Smoother and more airtight opening and closing of heavy-duty fans.

- Wind Resistance and Deflection: Service pressure 1.5–2.5 kPa, ultimate pressure ≥1.5×SLS → Safer for coastal/high-rise buildings.

Thresholds and Accessibility (AS 1428.1 definition)

Clear opening width: Standard configurations can reach ≥ 850 mm.

Low sill: Offers a low-sloping sill and concealed drainage nodes → ensuring both accessibility and waterproofing.

Indicators: Handle height, contrast, and swivel area are drawn according to AS 1428.1 design guidelines.

Watertightness/Airtightness and Energy Efficiency

Air tightness (75 Pa): Sliding doors ≤ 2.5 L/s·m², Hinged doors ≤ 1.5 L/s·m² (target value).

Rated differential pressure for water seepage resistance: 300–600 Pa (depending on door type/scenario).

Overall door energy efficiency: Uw≈2.0–2.6, SHGC≈0.25–0.45 (double silver Low-E + warm edge + multiple seals) depending on configuration.

Available: AS 2047/AS/NZS 4420 report page + WERS tab.

BAL and Coastal Corrosion Resistant

Clear opening width: Standard configurations can reach ≥ 850 mm.

Low sill: Offers a low-sloping sill and concealed drainage nodes → ensuring both accessibility and waterproofing.

Indicators: Handle height, contrast, and swivel area are drawn according to AS 1428.1 design guidelines.

Aluminum Windows

Thermally broken aluminum system

PA66+GF thermal break strip: Commonly used 14–28 mm; the wider the strip, the lower the frame Uf (U-value) → more stable insulation in winter.

Overall window U-value (Uw): 1.8–2.4 W/m²·K can be achieved with common double-glazed configurations → reducing air conditioning/heating load.

Condensation control at the edge: Warm edge spacers can further reduce edge heat transfer by approximately 10–15% compared to aluminum spacers → reducing condensation at window edges.

Frame wall thickness & cavity: Door and window frames ≥1.8–2.0 mm, multi-cavity + isobaric cavity → improving structural and watertight stability.

Available: ISO 10077 calculation sheet + AS 2047/AS/NZS 4420 performance summary (sample).

Low-E Insulating Glass

Glass Ug: Double-silver/Triple-silver Low-E, Ug≈1.0–1.6 W/m²·K (24–28 mm structure, inert gas filling).

Solar Heat Gain Coefficient (SHGC): 0.22–0.45 (adjustable with climate and orientation) → Suppresses heat gain in summer/retains heat in winter.

Visible Light Transmittance (VT): 0.45–0.70, balancing light transmission and glare control.

Triple-glazed option: 32–40 mm IGU available in extremely cold/high-wind areas, further reducing Uw/SHGC.

Available: Glass configuration table + AS 1288/AS/NZS 4666 compatibility instructions.

Sealing and Airtightness System

Multi-layer sealing: EPDM main seal + back groove foam strip + dustproof strip (3–4 layers) → Reduces air permeability.

Air tightness (75 Pa): Window ≤ 1.5 L/s·m² (target value) → Significantly reduces cold seepage in winter and heat seepage in summer.

Water resistance rating: 300–600 Pa (window type and wind zone of the project) → No internal seepage during heavy rain.

Pressure equalization chamber/drainage: Built-in pressure equalization chamber in the profile + concealed drainage → Stable discharge under wind and rain protection.

Available: AS/NZS 4420 airtightness/watertightness test sheet + detail drawings.

Thermal Imaging and Performance Verification

Thermal Image Comparison: Indoor/outdoor thermal images of the wall-mounted sample window are taken to reveal temperature differences/cold bridge locations.

Whole Window Energy Efficiency Label: A WERS (Uw/SHGC/VT) example is provided → directly applicable to NatHERS/Section J.

Project-Based Example: Common casement windows: Uw≈1.9–2.2, SHGC≈0.28–0.40 (Double Silver Low-E + Warm Edge).

Deliverables: Calculation assumptions, test conditions, photographic records, and traceability numbers.

Curtain Wall: Framed / Modular / Spider-like

Type Testing (AS/NZS 4284 Project Sample Section)

Air Infiltration (75 Pa): ≤ 1.0 L/s·m² (Target/Typical).

Static Pressure Water Resistance: 450–750 Pa is commonly used; higher levels are possible in high-wind areas (determined by calculation).

Structure/Deflection: Mid-span deflection L/250 (typical service limit), column/beam displacement coordination verified by actual measurement.

Displacement Compatibility/Inter-story Deformation: Provided according to the scheme **±displacement capacity** (e.g., ±15–20 mm) → adaptable to main structural deformation.

Deliverables: 4284 test plan, photographs, and report summary (including rated differential pressure, leakage, and deflection records).

Glass and Thermal Performance

Glass: Insulating glass, 24–32 mm (standard); laminated glass + Low-E combination available to improve acoustics and safety.

Thermal Parameters: Use U/SHGC/VT as input parameters for Section J/JV3; zone/facade comparison tables available.

Acoustics (Optional): Common curtain wall IGU Rw 35–42 dB; laminated/asymmetric cavities up to Rw 40–45 dB.

Corrosion Resistance and Maintenance (Coastal/Industrial Areas)

Corrosion Category: C3–CX as specified in AS 4312;

Coating System: AS 3715 (powder) or equivalent coastal grade solution;

Maintenance: C5–CX sites are recommended to be cleaned every 1–3 months. A maintenance record template is provided.

Certifications and Guarantees for U.S. Projects

For Australian window, door and curtain wall projects, third-party testing and certifications are critical for NCC compliance, council approval and long-term performance.

Our systems can be tested and supplied to comply with NCC 2022 and key Australian Standards such as AS 2047 for windows and external glazed doors, AS 1288 / AS/NZS 2208 for glass selection and safety, and AS 4284 for façade performance, together with Australian certification marks and dependable warranties for your projects.

Australian Market Certifications

We provide test reports and certifications to Australian Standards, including AS 2047, AS 1288, AS/NZS 2208 and AS 4284. Where required, we can also assist with WERS energy ratings and other project-specific compliance documentation.

After-Sales Service

Our team offers responsive after-sales support for Australian projects, including spare parts supply, remote troubleshooting and coordination with local installers to keep your window, door and curtain wall systems performing as designed.

APRO’s Project Services for Middle East Australia Projects

Why Choose Apro?

At APRO, we help Australian builders, contractors and façade engineers deliver compliant, durable window, door and curtain wall systems. Every solution is engineered around NCC 2022, AS 2047, AS 1288, AS 4284 and your local wind, bushfire and energy rating requirements.

From design and shop drawings to fabrication and packing, we focus on stable quality, on-time delivery and value-engineered options—so your façade project in Australia stays compliant, on budget and on schedule.

Apro - Solutions Team

R&D Team

Designing project-specific aluminum window, door & façade solutions.

Marketing Team

Connecting our factory with distributors, contractors and project owners worldwide.

Production Team

Lean manufacturing to deliver stable quality and reliable lead times.

Quality Assurance Team

Inspecting every profile, finish and accessory before it leaves the factory.

Customer Service Team

Coordinating drawings, orders and after-sales support with quick responses.

Overseas Installation Team

Providing on-site supervision and technical guidance for projects worldwide.

FAQ for Australia

Are your aluminium windows and doors compliant with NCC 2022 and AS 2047 in Australia?

Yes. Our systems can be tested and supplied to meet NCC 2022 and AS 2047 requirements for structural performance, air infiltration and water penetration. This means you can confidently specify NCC 2022 compliant aluminium windows and doors in Australia for residential and commercial projects.

What type of aluminium windows are best for coastal homes in Australia?

For coastal projects we recommend marine-grade aluminium profiles, AAMA/AS-certified powder coating and stainless-steel hardware to resist salt spray and UV. These configurations are ideal if you are looking for aluminium windows for coastal homes in Australia that maintain colour and performance over time.

Can you supply BAL-rated bushfire windows and doors for Australian projects?

We can design and configure systems for BAL-rated zones, including appropriate glazing, seals and hardware, and work with your consultant to meet local requirements. If your project needs BAL bushfire rated aluminium windows and doors in Australia, our team can propose suitable profiles and glass packages.

How do your curtain wall systems handle high wind and cyclonic regions in Australia?

Our curtain wall systems are engineered based on site wind loads, building height and pressure coefficients, and can be tested to AS 4284 where required. This ensures suitability for high wind and cyclonic region curtain wall systems in Australia.

Do you offer energy-efficient double glazed aluminium windows for Australian homes?

Yes. We provide thermal-break frames with double or triple glazing options to help achieve better U-values and SHGC for different climate zones. These energy efficient double glazed aluminium windows in Australia can support NatHERS, BASIX and other energy targets.

What is a thermal break aluminium window system and why is it important in Australia’s climate?

A thermal break window uses an insulating strip between inner and outer aluminium to reduce heat transfer and condensation. This is especially important for thermal break aluminium window systems for Australian climate zones, from hot coastal areas to cooler inland regions.

Can you provide engineering and shop drawings for commercial curtain wall projects in Australia?

We supply full façade engineering support, including layout drawings, section details, fixing design and material schedules for review by your local engineer. This makes it easier to coordinate commercial curtain wall design and shop drawings in Australia with architects and builders.

How do you package and ship aluminium windows and curtain wall materials from China to Australia?

Products are packed in custom steel or timber crates with corner protection, labels and loading plans, then shipped by sea to major Australian ports. Our process is optimised for shipping aluminium windows and curtain wall systems from China to Australia safely and efficiently.

What is the typical lead time for custom aluminium windows and curtain wall systems for Australian projects?

Lead time depends on project size and finish, but most orders ship within 6–10 weeks after drawing approval and deposit. We confirm a schedule up front so you know the lead time for custom aluminium windows and curtain wall systems in Australia before placing the order.

Do you offer local support and after-sales service for aluminium windows and curtain walls in Australia?

Yes. We provide remote technical support, spare parts and can cooperate with your local installers or façade contractor for site guidance. This ensures reliable after-sales support for aluminium windows and curtain wall projects in Australia throughout the life of the building.