Aluminum Door and Window & Curtain Wall Solutions For USA

We deliver code-ready façade systems for U.S. projects: energy-efficient, coastal and cold-climate options, fast installation via factory prefabrication, with design-assist, shop drawings, and after-sales support.

Certifications and Guarantees for U.S. Projects

For U.S. window, door and curtain wall projects, independent certifications are essential for code approval, energy compliance and owner confidence.

Our systems can be supplied with NFRC-certified thermal performance data and CSA C&US test reports for structural, air and water performance, together with other relevant standards and a dependable warranty for your North American projects.

U.S. Market Certifications

We provide NFRC ratings for U-factor, SHGC and visible transmittance, plus CSA C&US test reports for structural, air and water performance. Additional options include Energy Star and other project-specific standards where required.

After-Sales Service

Our team offers responsive after-sales support for U.S. projects, including spare parts supply, remote troubleshooting and coordination with installers to keep your façade systems performing as designed.

Challenges and Solutions We've Encountered in US Projects

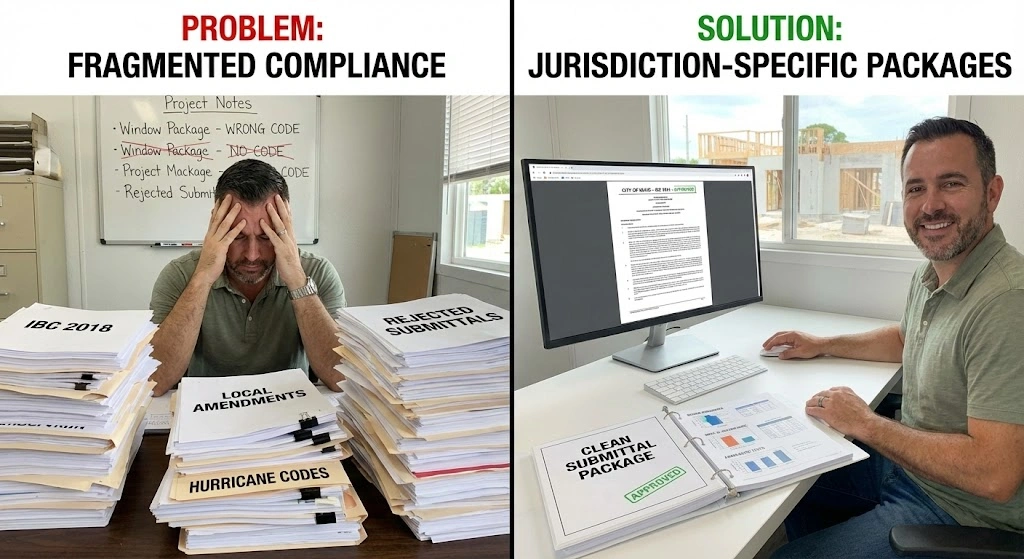

Different codes and AHJs asking for different things

Pain in the U.S.:

On one project you follow IBC and IECC; on the next, the local authority has its own amendments, hurricane requirements, or special testing lists. Submittals bounce back because the window or curtain wall package doesn’t clearly reference the right IBC, IECC, NFRC, AAMA or ASTM criteria for that specific city or county.

Our solution:

We build each package around the exact U.S. jurisdiction: IBC edition, local energy code, hurricane or non-hurricane zone. Our engineering sheets and shop drawings clearly list design pressures, NFRC U-factor/SHGC data and relevant AAMA/ASTM tests, so the glazing contractor can submit one clean, code-specific package to the AHJ and get approvals faster.

Wrong system or rating for wind / hurricane zones

Pain in the U.S.:

Storefront gets installed where a curtain wall or impact-rated system is required; design pressures are underestimated; or the glass package doesn’t meet Florida Building Code or Miami-Dade criteria. Result: failed inspections, forced upgrades, and units that have to be removed and replaced after they’re already installed.

Our solution:

Before fabrication we run ASCE 7 wind-load checks and confirm required performance class (non-impact, impact, missile level, etc.) for each elevation. We then select the appropriate U.S. hurricane-rated window, door or curtain wall system, supply engineering calculations, and mark design pressures on the shop drawings so installers know exactly which units go where.

Water and air leakage failures during field testing

Pain in the U.S.:

ASTM E1105 water tests and ASTM E783 air-leakage tests are now standard on many U.S. projects. Even if the lab-tested system performs well, field tests fail because perimeter seals, anchors or stack joints were not installed correctly.

Our solution:

We provide installation manuals, perimeter details and QC checklists tailored to U.S. field-testing standards. Critical sealant steps, shim locations and drainage paths are clearly shown on the drawings. We can support pre-construction mockups and site training, helping glazing crews pass AAMA 502/503 field tests the first time and avoid costly tear-outs.

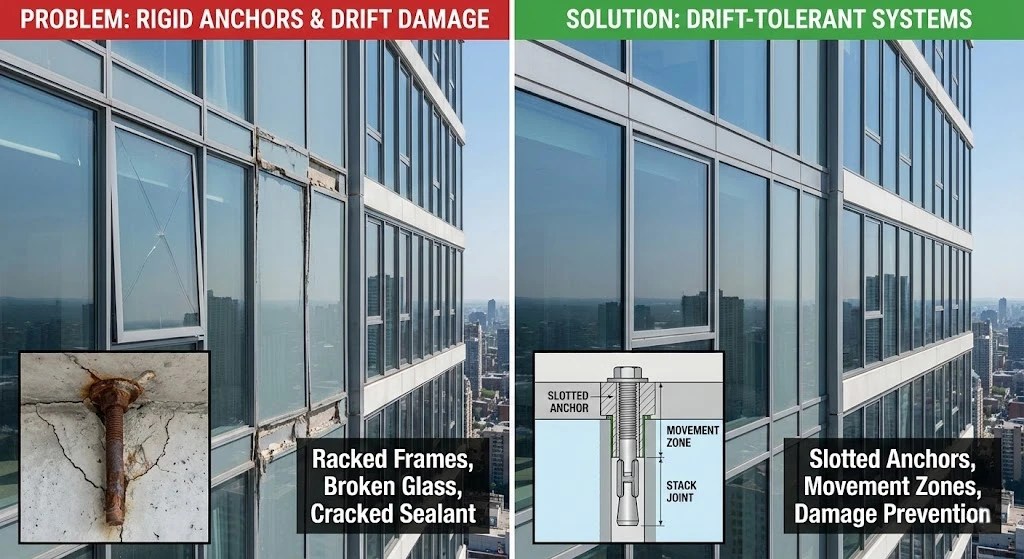

Seismic drift and building movement cracking frames and glass

Pain in the U.S.:

In seismic regions and high-rise projects, floor slabs move under wind and earthquake loads. When curtain wall and window wall anchors are fixed too rigidly, drift causes racked frames, cracked sealant joints or even broken glass during testing or shortly after occupancy.

Our solution:

We design seismic- and drift-tolerant curtain wall and window wall systems for U.S. projects with stack joints, slotted anchors and movement zones sized to the project’s drift requirements. Our details clearly indicate where joints must be left free to move, reducing the risk of damage when the structure deflects under real loads.

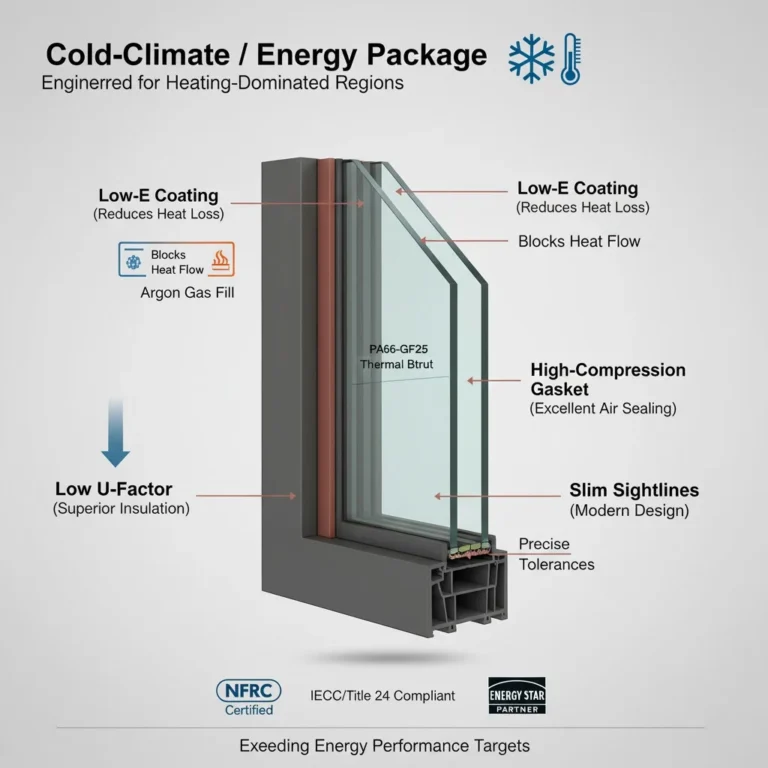

Meeting U.S. energy-code targets with real products on site

Pain in the U.S.:

The energy model assumes certain U-factors and SHGC values, but by the time submittals and substitutions are done, the actual windows don’t match the IECC or state energy-code assumptions. Inspectors ask for NFRC labels and documentation that the installed products really meet the specified ratings.

Our solution:

We propose NFRC-rated U.S. aluminium window, door and curtain wall configurations that align with the project’s energy model from the start. NFRC certificates and label information are included in the submittal, and we help the contractor match each elevation’s glass and frame combination with the correct rating, so energy inspectors can verify compliance easily.

Fast-track schedules and out-of-sequence installation

Pain in the U.S.:

On many U.S. projects the structure, MEP and interiors are pushed ahead while façade design is still evolving. Openings get changed, anchors are poured in the wrong place, and glazing crews arrive to find that the actual conditions don’t match the drawings, leading to RFIs, change orders and night-shift rework.

Our solution:

We support fast-track U.S. construction with early coordination models, flexible anchoring strategies and clear tolerance zones. Optional adjustable anchors and filler profiles let installers adapt to minor structural changes without remaking entire units. We also provide quick-turn revisions to shop drawings when RFIs arise, helping the façade stay aligned with the jobsite schedule instead of slowing it down.

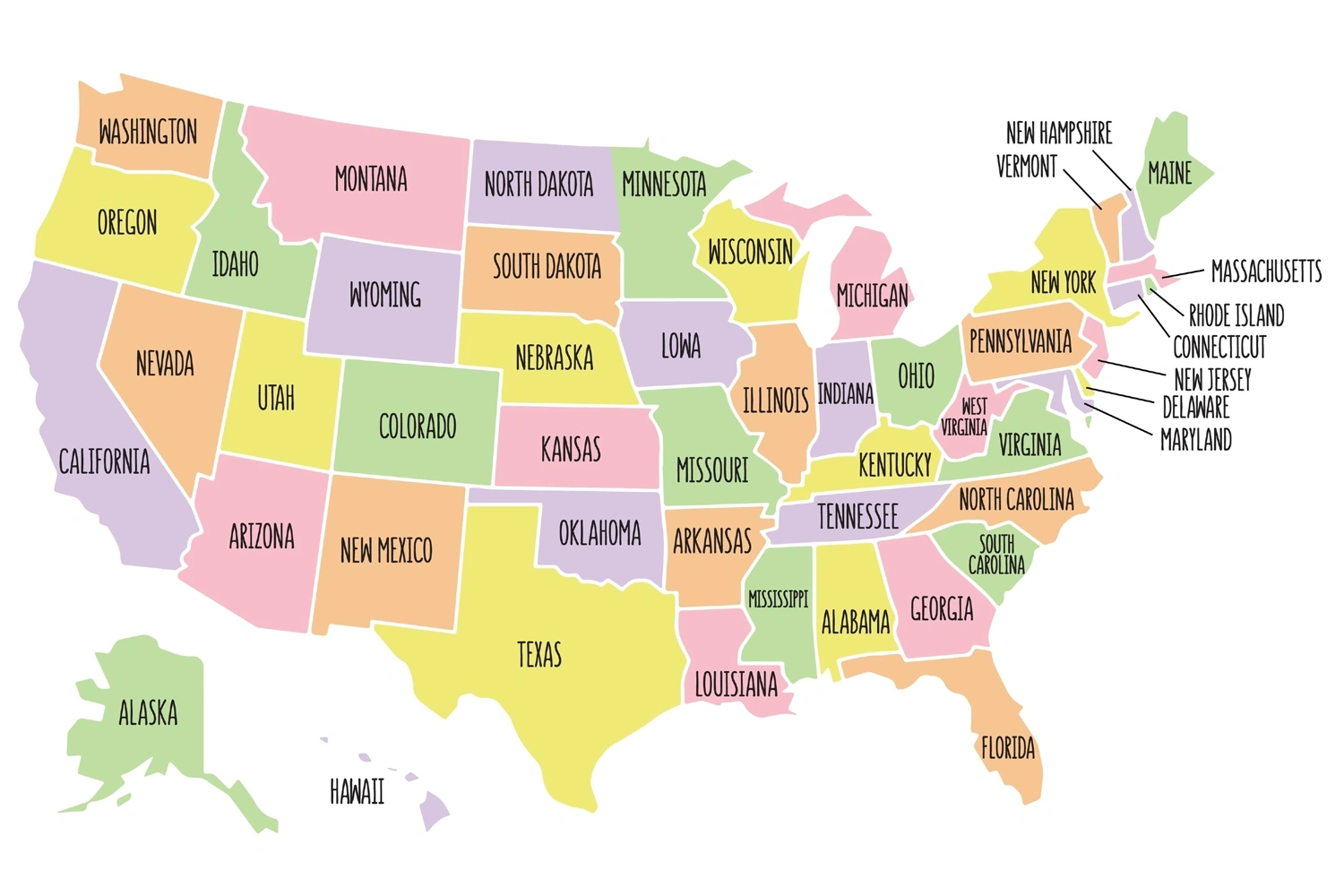

Designed for U.S. Climates

Application Scenarios

Market Challenges in the U.S.?

U.S. door and window projects face diverse climate zones, tightening energy codes, high labor costs, and strict performance testing.

- State/city regulatory difference

- Multiple climate zone requirement

- Strict energy efficiency regulations

- Strict energy efficiency regulations

- Air tightness and water tightness requirements

- Snow load and condensation control standards

- Hurricane resistance and wind pressure standards

- Compressed project timelines

- High labor and hoisting difficulty

- Noise and sound insulation rating

Our solution addresses these constraints with standardized, test-proven systems, modular delivery, and a documentation set that keeps architects, GCs, installers, and inspectors aligned from pre-con through punch-list.

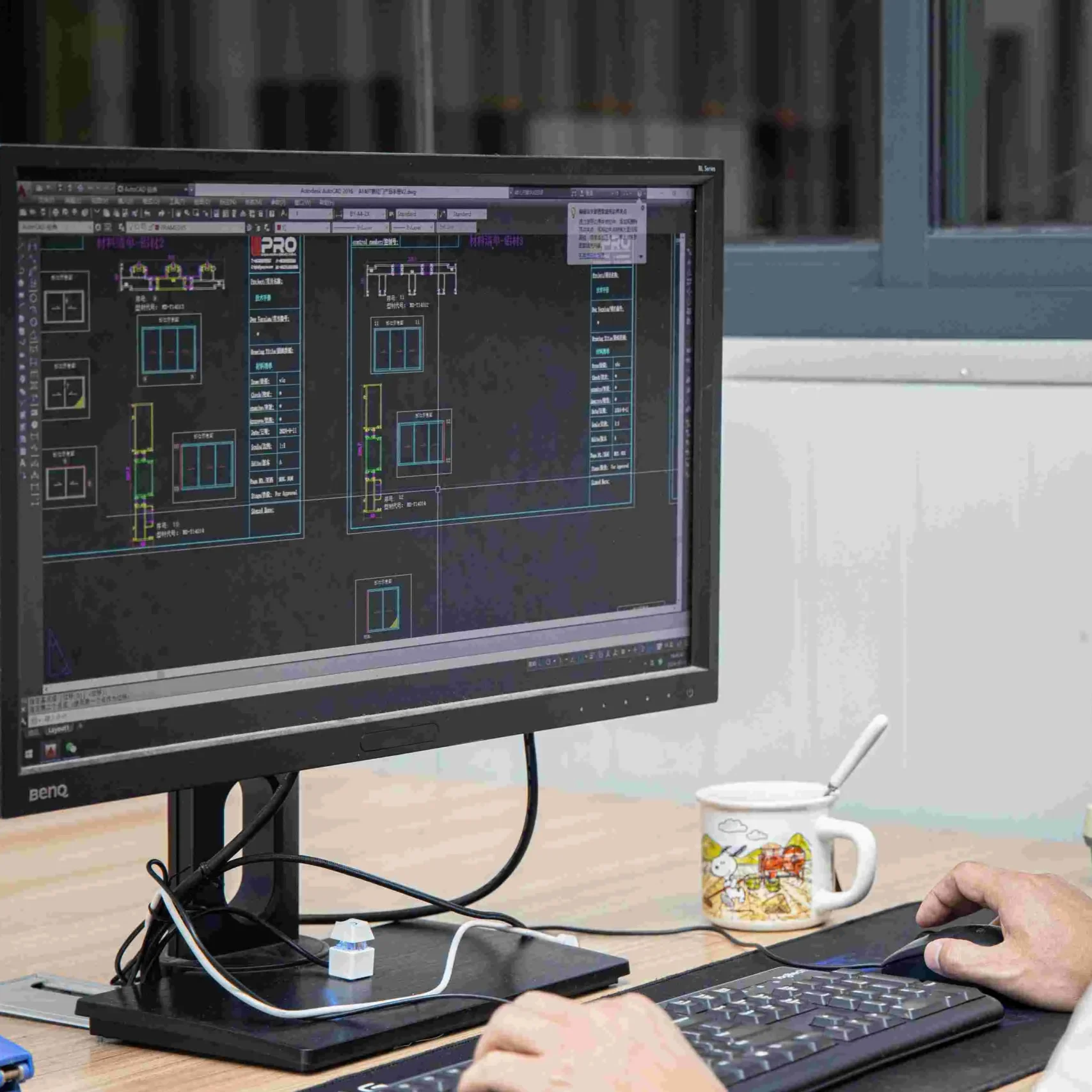

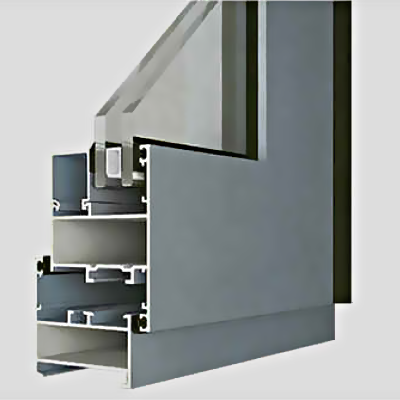

Aluminum Door Typical Details

Aluminum Windows Typical Details

Curtain Wall Typical Details

Our factory's production process is transparent.

1,Design

2,Material Preparation

3,Machinery Setup

4,Cutting and Machining

5,Frame Construction

6,Glass Fitting

7,Hardware Setup

8,Quality Cntrol

9,Packing

10,Shippment

Aluminum Doors and Windows Solutions in the United States - FAQ

What standards and regulations do we meet in the United States?

We align with U.S. project requirements using NFRC (thermal ratings/labels), NAFS/WDMA and ASTM E283/E331/E330 (air, water, structural) for windows/doors, and AAMA/ASTM series for storefront/curtain wall. Targets are confirmed in submittals per the jobsite jurisdiction.

Can you provide NFRC ratings and labels?

Yes—NFRC thermal simulations and documentation can be provided. Project labels are available through program partners/component libraries when the final configuration matches the rated build-up.

What do the NAFS/ASTM indicators represent?

DP (Design Pressure) is the design load; ASTM E283 = air infiltration, E331/E547 = water penetration, E330 = structural load. Your specification will state minimum DP and allowable AI/Water/Structural values.

Do you provide PE stamps/structural calculations?

Yes—project calculations, anchor design and PE stamps can be arranged through licensed third-party engineers in most states.

How to resist corrosion in coastal environments?

Specify AAMA 2604/2605 finishing, 316 stainless hardware, corrosion-resistant fasteners/sealants, and pressure-equalized drainage. Salt-spray or coating reports can be provided.

How to arrange delivery and logistics?

Typical timeline: design-assist → quote → submittals → sample/testing (if needed) → production → crated shipment with ID labels, manuals and spare kits. INCOTERMS and transit options are quoted per project.

Warranty and after-sales service?

Standard warranties cover structure, hardware and finishes for specified terms. After-sales support includes spare availability, remote guidance and response SLAs. Full policy available on request.